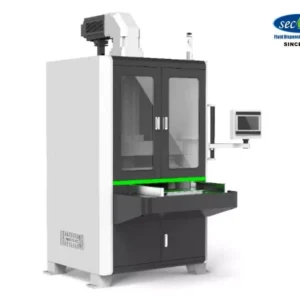

MEA materials cutting / stamping machine for multi purposes – SEC-H500-BC

Achieve hydrogen fuel cell MEA 3CCM, frame, GDL, 7CCM and other materials high precise cutting.

MEA materials cutting / stamping machine for multi purposes – SEC-H500-BC

Achieve hydrogen fuel cell MEA 3CCM, frame, GDL, 7CCM and other materials high precise cutting.

MEA Seven-in-one automatic packaging line – SEC-H500-7M

Realize hydrogen fuel cell GDL+5CCM+GDL dispensing, laminating and pressing

Metal plate/composite plate gasket press-fit machine – SEC-H500-TP

Realize the press-fit / lamination of metal plate, graphite plate, composite plate’s gasket(s).

PEM Electrolyzer adhesive dispenser – SEC-H800

This is a multi purposes dispensing machine, it is designed to developed for larger sizes metal plate dispensing needs. The equipment is compatible to different sizes and shapes of bipolar metal plates. The visual auto position dispensing system is stable and reliable for high precision works. The machine is customized to process and work with variety of dispensing valves for different materials and plates.

SEC – Flexible stacking line for graphite bipolar plate

Semi-auto high compatibility, compact space PEM FC package system with manual stack’s locking system, flexible works for different structures.

The design of this graphite plate stacking system is to develop a flexible assembly system for the stacking and assembly of different structures of hydrogen fuel cell stacks. The loading and unloading of wire materials is realized by robots. The stacking of materials is completed by the robot, the high-precision servo press ensures the precise pressure of the stack, the studs are manually locked, and the multi-directional airtightness test of the stack is carried out by the flow method.

SEC – Fuel cell stacking system – Multi purposes

High scalability, high compatibility meet various production needs in different stages.

The design of the system stacking line aims to develop a fully automatic assembly line for stacking and assembling PEM hydrogen fuel cell battery stacks. The loading and unloading of materials in this line is realized by robots, stack end plates, current collector plates, bipolar plates, etc. The stacking of materials is completed by the robot, the high-precision servo press ensures the precise pressure of the stack, the visual alignment system ensures the accuracy, the stack is automatically tightened, and the multi-directional air tightness test is performed on the stack by the flow method.