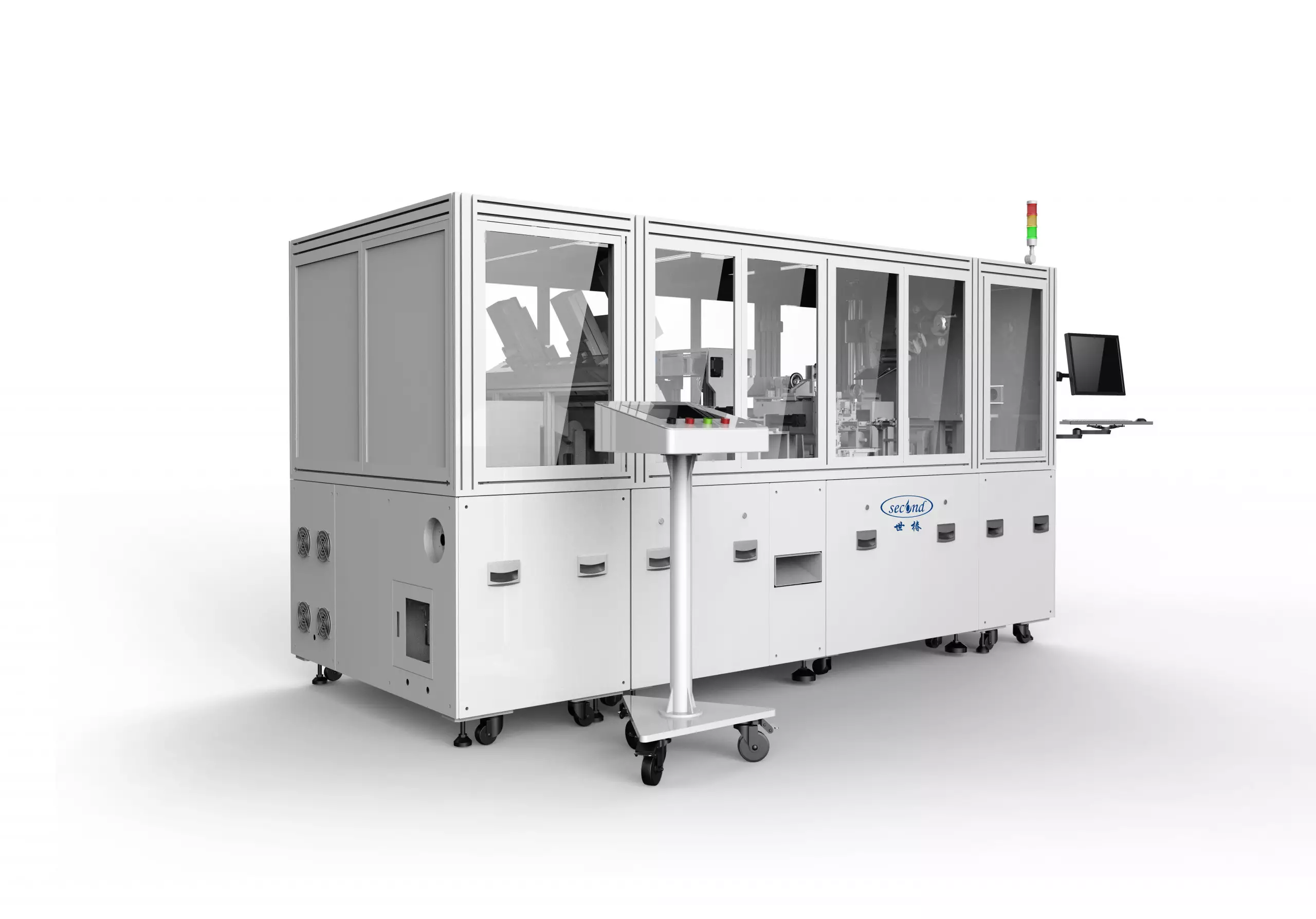

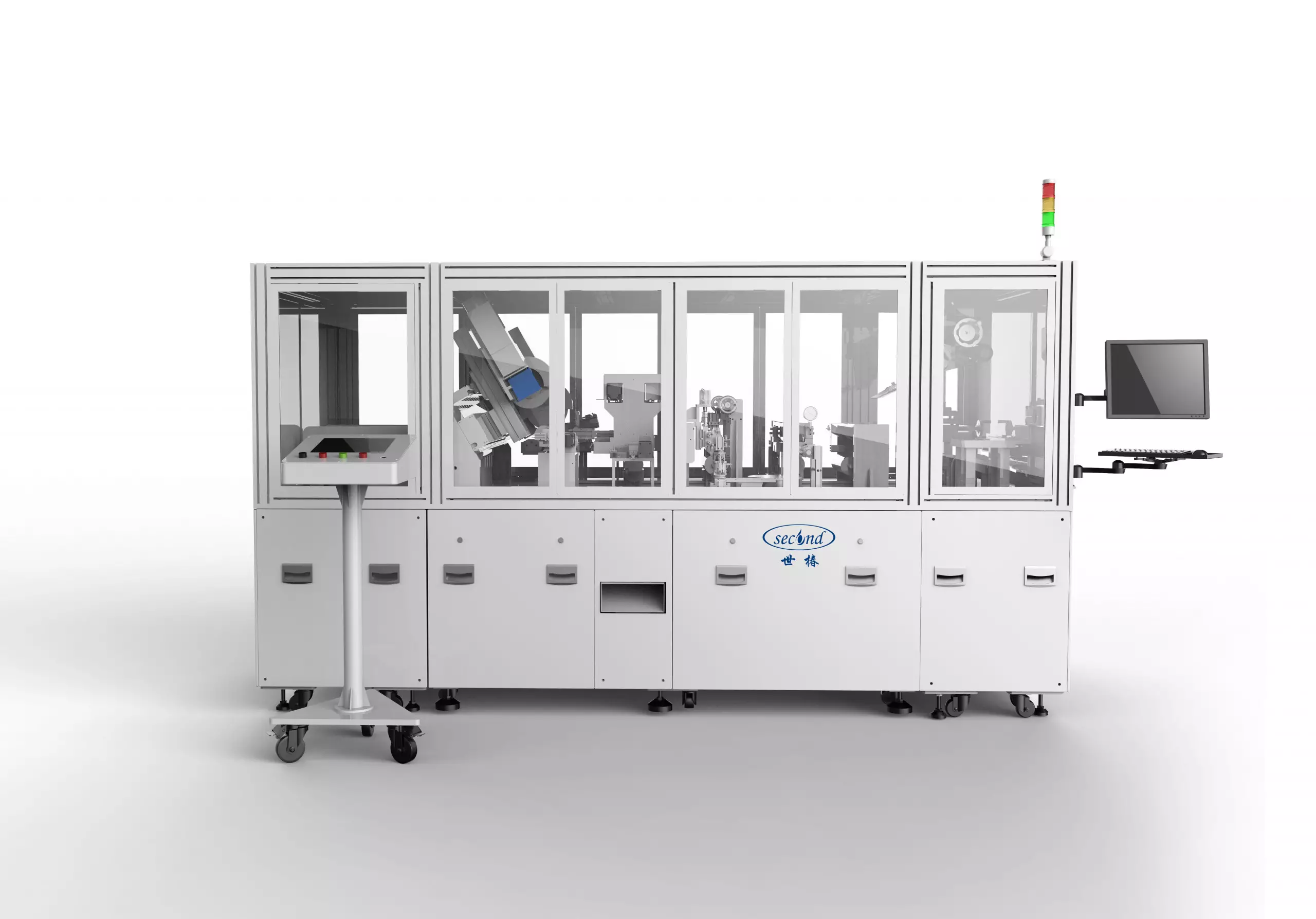

Automatic cartridge grooming machine (trimming, leak testing, O-ring assembling, labeling, recording) SEC-S1860WT

Automatic cartridge grooming machine (trimming, leak testing, O-ring assembling, labeling, recording) SEC-S1860WT

The equipment is suitable for household RO cartridge element grooming. It will trim off the cut edges of the element, perform leak test, assembling O-ring, label barcode, scan and record it fully automatically. It works for cartridge elements sizes between 1810-3013.

This is RO and water filter fabricating machines and equipment production floor. From the house to industrial types of RO, they were produce in this department.

The machine is effective and efficient for different type of element withing the ranges.

|

Model |

SEC-S1860WT |

|

Suitable cartridge element |

1810-3313 |

|

Leak testing |

Vacuum |

|

Blade rotate speed |

1-72 rpm |

|

Element loading method |

Automatic |

|

Cutting speed |

0.1-10mm/sec |

|

O-ring feeding |

Vibrating bowl |

|

Cutting accuracy |

±0.2mm |

|

O-ring assembling |

Automatic |

|

Cutter lifespan |

100000 times |

|

Cartridge trimming |

Auto pull-off |

|

Vacuum testing range |

<-99kp |

|

Cutting method |

Servo motor drive |

|

Pressure tolerance |

±1kp |

|

Operating method |

PLC + touchscreen |

|

Capacity |

200PCS/H(1812) |

|

Power consumption |

6KW |

|

Power supply |

AC220V/50HZ |

|

Machine dimension |

L3640*W1640*H1739mm |

|

Machine weight |

660KG |

With this machine, operator can load about 100 units of spiral-wind cartridges on to its material bin, and the machine will automatic feeding cartridge to its place one by one. It will start to do edges trimming, edges pulling, adding O-rings, air-tightness detection, labeling and record barcode, and automatic unloading. This is a Smart-machine, it will automatically sort out the air-test failed cartridge and drop it to a separated bin.

Basically, the operator only need to load the ungroomed cartridge element onto the bin, set parameter, and press start to process. This is a high degree of automation, unmanned, safe, stable quality, high production efficiency machine. One person can watch multiple sets of equipment at the same time.

-1200x208-1.webp)

Our two-component In-line automated vacuum potting system machine is often used in the LED driver, power supply dispensing, with this encapsulated process, the product is heat dissipation, moisture-proof, waterproof, and flame retardant.

EMI and FIP dispensing techniques are widely use in the telecommunication and transportation industries. With the rapid development of communications, electric vehicles, and personal wireless electronic gadgets, these products are often required to connect and interact between each others. However, the signals sometimes interfere with the others, so need to be filtered or shielded. To improve and control the electromagnetic signals, engineers can redesign the entire product, or it can apply EMI shielding materials to filter or shield. Shielding is relatively economical and easy to achieve, it is done basically by adding shielding gasket. Our dispensing machine can directly produce different sizes of triangular shapes or D-shape filtering gaskets, these gaskets can appear in different shapes and is directly applying to the products. The dispensing machine equips with special adhesive material dispensing valve to apply directly, and without post-processing. The machine is intelligent, precise, but user-friendly, without complicated installation, or setup. In addition to the above functions, this type of dispenser equipment can also dispense FIP adhesive glue, and thermal interface material. The equipment is not only precise, but also multi-purpose, which is convenient for various type of storage battery, and electronic product applications.

Dispensing equipment are important for various EMS (electronic manufacturing service) productions. Electronic product processing service industry is indispensable to modern life, because many products are now equips with electronic and become more intelligent. These products are becoming more and more complex, precise and tiny in size. And for consumer product, their production volume also in large production and fast turnover. Therefore, it is necessary to use automated equipment, or even fully automated production lines to produce to meet apply the materials. With the automatic dispensing robots, it is possible to catch up with the capacity and demands. And more importantly, to improve economic efficiency to maximize economic of scale, and so to reduce unit prices to enhance competition. Very often in this type of production, the uses of dispensing machines or equipment is inseparable. In this production process, the glue dispenser is usually used to assist in the functions of fixing, connecting, protecting, dissipating heat and so on between parts and components. Our glue dispensers can directly add the relevant materials to the specified positions accurately and quickly as required.

Two-component materials’ encapsulating and casting production are important to enhance electronic products. No matter if your product is for business selling, or for household consuming, nowadays everyone has higher quality requirements and expectations. Furthermore, the protection of the product is not only to optimize the function of the product, but also to prolong the service life of the product, thereby reducing production waste. In electronic products the parts and components are generally composed of different metals and sensitive chemical combined materials. The more precise the product, the more high-tech the product it is, with this, it requires higher protection, so that it can be optimized according to the requirements. In doing so, it can state of long-term operation without being affected by the surrounding environmental conditions. Our two-component potting machines are specially designed for this production, as well as our vacuum encapsulating and casting potting machines. These machines can accurately degas the two-component adhesive materials base on the ratio, meter, mix, and homogenously and continually to the products. These materials cannot be applying manually, they need to use machines, which can be supplied in large quantities, continuously, accurately, and for long time of works. With the materials provided by such equipment, the product will have better protection, heat dissipation, waterproof, moisture-proof, encryption (to protect the circuitry design, and components used).

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

CE, UL, ISO 9001, and RoHS compliance for global markets.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

This is semi-automatic industrial reverse osmosis (RO) cartridge element rolling, it can roll SWRO, BWRO, 4040-8040 sizes of elements. It will need two people to operate at the same time. It is MMI type of machine, in the man-machine interaction area there’s safety light curtain installed for good protection. The machine comes with rolling table, adhesive dispensing, winding, ultra-sonic welding, and outer taping system, all in one. It is for mass production, and good for quick-change over to produce different sizes of the elements compare to the full-automatic machine.

The equipment is suitable for fixed-length cutting of membranes, spacer, carrier membrane, etc. in the household RO cartridge element production process. It can cut products with a width of 150-1100mm. It is designed for high speed, high accuracy, and high capacity production.

The equipment is suitable for slitting different sizes of carbon block fiber rods. User friendly design for efficient, and effective operation.

The equipment is suitable for industrial RO cartridge edges trimming process. The equipment uses high-quality materials, stable in use, accurate cutting, safe and durable.