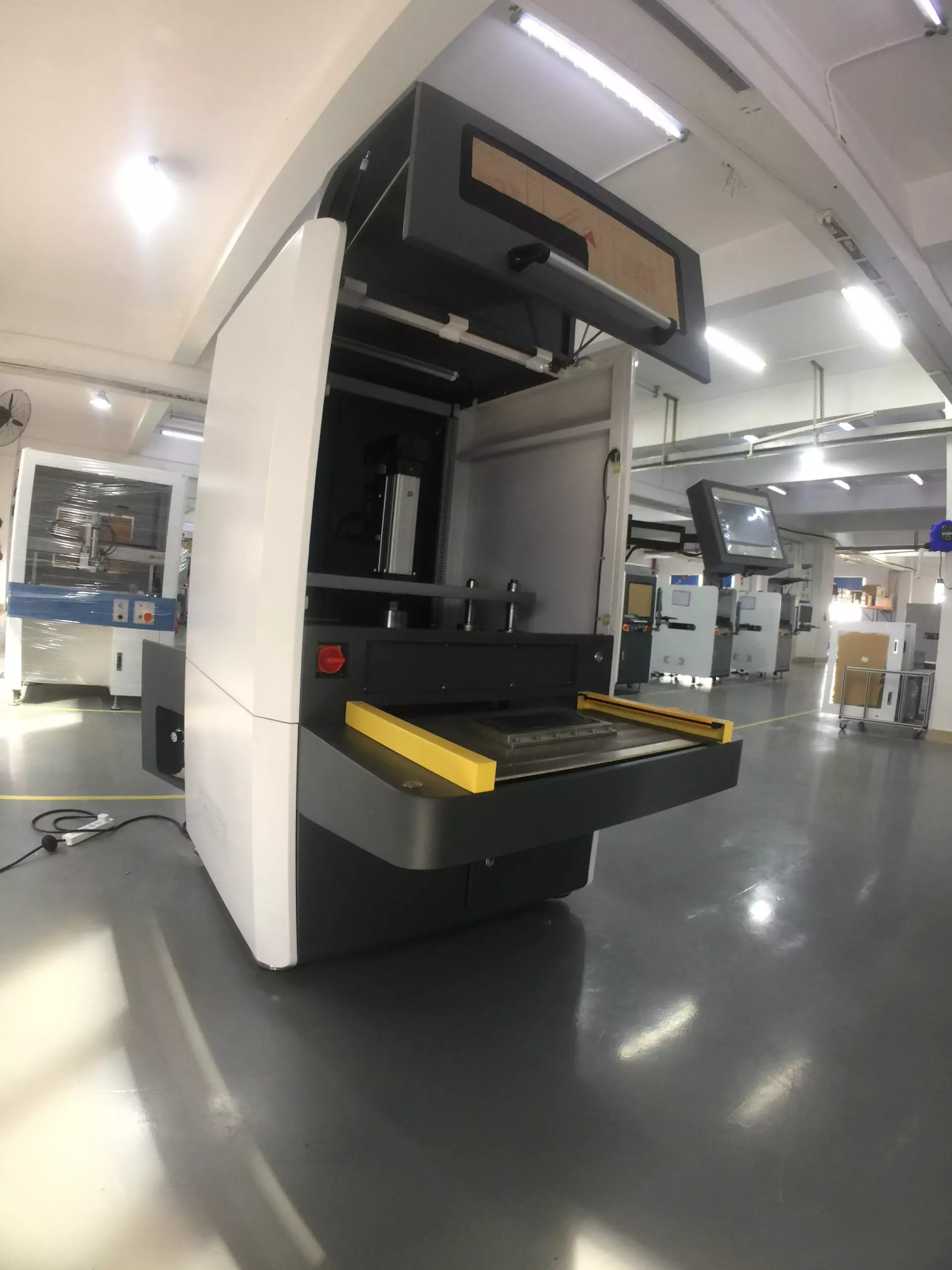

MEA materials cutting / stamping machine for multi purposes – SEC-H500-BC

Achieve hydrogen fuel cell MEA 3CCM, frame, GDL, 7CCM and other materials high precise cutting.

MEA materials cutting / stamping machine for multi purposes – SEC-H500-BC

Achieve hydrogen fuel cell MEA 3CCM, frame, GDL, 7CCM and other materials high precise cutting.

Hydrogen fuel cell battery is getting more important as an alternative power source for automotive vehicles, and also more and more stationary power supply are being developed. It is also a type of green energy, it has zero emission. Most of the machines and production lines we listed on this web-site have been built and sold to many clients already, and they have been proved success and reliable.

The company has begun to enter into the field of hydrogen fuel cell equipment in 2014. After years of researches and developments, combined the good experience in automated adhesives dispensing knowledge and the hydrogen fuel cell battery fabricating know-how, the company has successfully developed and sold various type of PEM FC bipolar plate automatic dispensing, sealing, and packaging machines as well as production lines. We also provide the membrane electrode assembling, packaging, machine, and production lines as well as automatic battery stacking machine, air tightness testing machine, testing and inspecting machines, fully automatic stack system, assembly production lines and other related equipment. We have established a subsidiary company name Suzhou Second Hydrogen Energy Technology Co., Ltd for this section of business, Shenzhen Second Intelligent Equipment Co. Ltd. is the mother-company. Please feel free to contact us, we provide free evaluation, proposal, and looking into long-term cooperation partnership to develop the businesses, and gives the Earth one more green energy option.

Equipment introduction:

Hydrogen fuel cells have been developed for many years, and the current technology is very mature, and the scientists have solved many technical problems. Now it is necessary to break through the bottleneck of mass production, so that the cost of each battery stack can be greatly reduced. To achieve this, automatic equipment production must be employed. We have prepared it for you here. Welcome your inquiry, we provide standard equipment and custom equipment. Whether it is for business operation or environmental protection, it is beneficial for us to have more green new energy like H2FC.

Commonly used glue

Multi-valve picture display

|

Model |

SEC-H500-BC |

|

Applicable product range |

500(X)╳300(Y) ╳0.5(Z)mm |

|

Product dimensional accuracy after cutting |

≤±0.05mm |

|

Number of single cuts |

1-4PCS |

|

Rated cutting force |

20T(Electric cylinder) |

|

Pressure control accuracy |

0.5%FS |

|

Electric cylinder running speed |

0-40mm/s |

|

Electric cylinder repeatability accuracy |

≤±0.02mm |

|

Opening height |

100mm |

|

Working surface size |

600╳400mm |

|

Operating system |

PLC |

|

Power supply |

AC220V,50-60HZ 18Kw |

|

Machine footprint |

L1200╳W1100╳H2600mm |

|

Machine weight |

About 2300Kg |

|

Working environment |

Humidity:20-90%, Temperature: 0-40℃ |

Main functions:

Optional functions:

Project

The LED Drive Power, Machine SEC-3030C

Project Background

The LED drive power supply is a power converter that converts the power supply into a specific voltage and current to drive the LED to emit light. The Shichun glue potting equipment is used in the LED drive power supply to play a role in heat dissipation, moisture proof, waterproof, and flame retardant.

Project Features

Heat dissipation, moisture proof, waterproof, flame retardant

Project Advantages

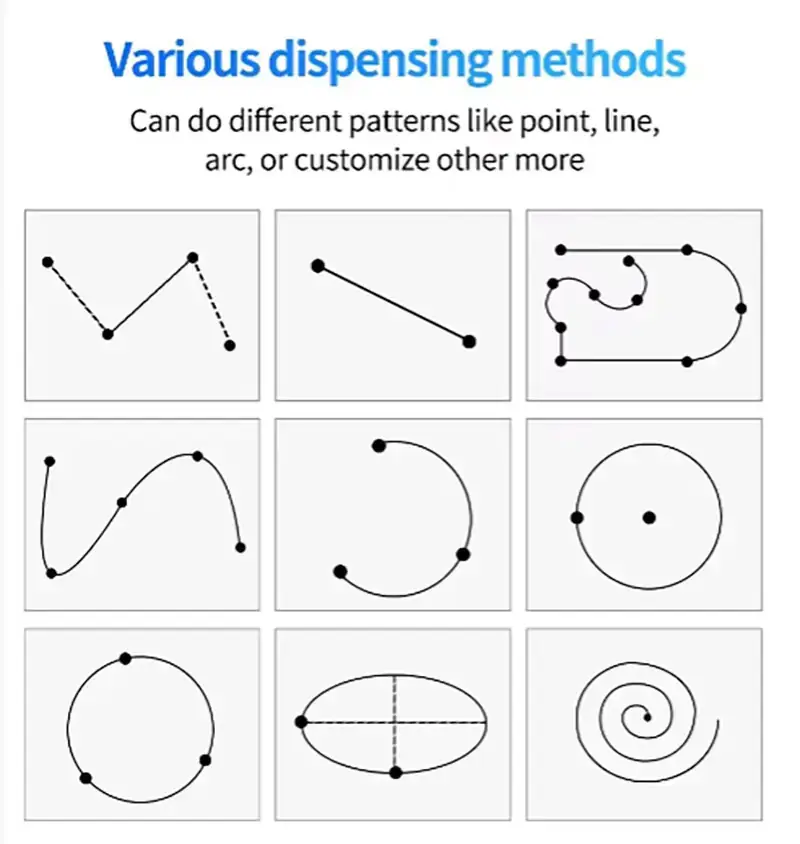

1. Three-axis linkage, capable of making arbitrary points, lines, arcs, circles, three dimensions, etc.;

2. Dynamic mixing, uniform mixing, no dripping;

3. Nano ceramic screw pump, good wear resistance;

4. 12CC screw pump, fast glue output speed, 30g/sec;

5. It has the function of pump pressure detection to ensure quality and safe production;

6. It has dynamic fault detection function to ensure quality and safe production;

7. Optional large-capacity storage barrel, saving feeding time and improving efficiency;

8. Online glue filling, without manual operation, automatic connection operation.

-1200x208-1.webp)

Our two-component In-line automated vacuum potting system machine is often used in the LED driver, power supply dispensing, with this encapsulated process, the product is heat dissipation, moisture-proof, waterproof, and flame retardant.

EMI and FIP dispensing techniques are widely use in the telecommunication and transportation industries. With the rapid development of communications, electric vehicles, and personal wireless electronic gadgets, these products are often required to connect and interact between each others. However, the signals sometimes interfere with the others, so need to be filtered or shielded. To improve and control the electromagnetic signals, engineers can redesign the entire product, or it can apply EMI shielding materials to filter or shield. Shielding is relatively economical and easy to achieve, it is done basically by adding shielding gasket. Our dispensing machine can directly produce different sizes of triangular shapes or D-shape filtering gaskets, these gaskets can appear in different shapes and is directly applying to the products. The dispensing machine equips with special adhesive material dispensing valve to apply directly, and without post-processing. The machine is intelligent, precise, but user-friendly, without complicated installation, or setup. In addition to the above functions, this type of dispenser equipment can also dispense FIP adhesive glue, and thermal interface material. The equipment is not only precise, but also multi-purpose, which is convenient for various type of storage battery, and electronic product applications.

Dispensing equipment are important for various EMS (electronic manufacturing service) productions. Electronic product processing service industry is indispensable to modern life, because many products are now equips with electronic and become more intelligent. These products are becoming more and more complex, precise and tiny in size. And for consumer product, their production volume also in large production and fast turnover. Therefore, it is necessary to use automated equipment, or even fully automated production lines to produce to meet apply the materials. With the automatic dispensing robots, it is possible to catch up with the capacity and demands. And more importantly, to improve economic efficiency to maximize economic of scale, and so to reduce unit prices to enhance competition. Very often in this type of production, the uses of dispensing machines or equipment is inseparable. In this production process, the glue dispenser is usually used to assist in the functions of fixing, connecting, protecting, dissipating heat and so on between parts and components. Our glue dispensers can directly add the relevant materials to the specified positions accurately and quickly as required.

Two-component materials’ encapsulating and casting production are important to enhance electronic products. No matter if your product is for business selling, or for household consuming, nowadays everyone has higher quality requirements and expectations. Furthermore, the protection of the product is not only to optimize the function of the product, but also to prolong the service life of the product, thereby reducing production waste. In electronic products the parts and components are generally composed of different metals and sensitive chemical combined materials. The more precise the product, the more high-tech the product it is, with this, it requires higher protection, so that it can be optimized according to the requirements. In doing so, it can state of long-term operation without being affected by the surrounding environmental conditions. Our two-component potting machines are specially designed for this production, as well as our vacuum encapsulating and casting potting machines. These machines can accurately degas the two-component adhesive materials base on the ratio, meter, mix, and homogenously and continually to the products. These materials cannot be applying manually, they need to use machines, which can be supplied in large quantities, continuously, accurately, and for long time of works. With the materials provided by such equipment, the product will have better protection, heat dissipation, waterproof, moisture-proof, encryption (to protect the circuitry design, and components used).

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

CE, UL, ISO 9001, and RoHS compliance for global markets.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

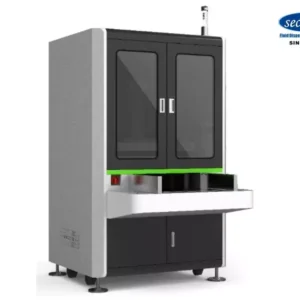

SEC-MEA inspection machine

High expansibility, high compatibility, meets different materials requirements, with smart auto material sizes inspection.

The system is designed for the MEA materials’ sizes auto inspection purposes, it can be working alone, or working in an inline system. It is developed for high-precision performance auto inspection of the MEA materials’ sizes. The loading and unloading of the materials are achieved by a robot. During the inspection, the system is able to apply a layer of high-transmission glass cover on the MEA to enhance the inspection as need. To ensure the smoothness of the material, the equipment uses a high-precision, high-definition line scan camera for scanning and imaging. After the inspection is completed, the robot is able to sort out OK or rejected products and unload them separately.

High scalability, high compatibility, suitable for screw stack production – SEC – Stacking machine system – Screw-type

The goal of designing the screw stacking line is to develop a fully automatic assembly line for the stacking and assembly of PEM hydrogen fuel cell screw stacks. The loading and unloading of wire/cable and materials is achieved by robots. The stacking of stack end plates, current-collector plates, bipolar plates and other materials is completed by robots. The high-precision servo pressing system to ensures the precise pressure of the stack, the CCD visual alignment system ensures the accuracy, the studs are manually locked, and the multi-directional air tightness test of the stack is carried out by the flow method accurately.

High scalability, high compatibility, suitable for strapping stack production – SEC– FC battery stacking system – Strap-type

The goal of designing strap-type stacking line is to develop a fully automatic assembly production line for stacking, assembling, and fastening of stacked battery cells. The stacking of current-collector plates, bipolar plates, and other materials is completed by robots. The high-precision servo pressing system is applied to ensure the precise pressure during the stack, the AI visual alignment system ensures the accuracy, the straps are automatically welded, and the stack is airtight tested in multiple directions by the flow method.

Air tightness testing machine (compatible with bipolar plate, and MEA air tightness testing need, multi-purposes) – SEC-H500-AT

This is multi-purposes machine, it can realize the air tightness detection of hydrogen fuel cell bipolar plate, MEA monolithic, and multi-sheet/layers of air-tightness test.