SEC-100TD standard included as below 6 parts.

(please check and see if the below parts are fully received when machine is arrived)

● Main unit

● Syringe adaptor

● Syringe holder

● Ø6 Pneumatics tube

● Power cord

● Foot switch

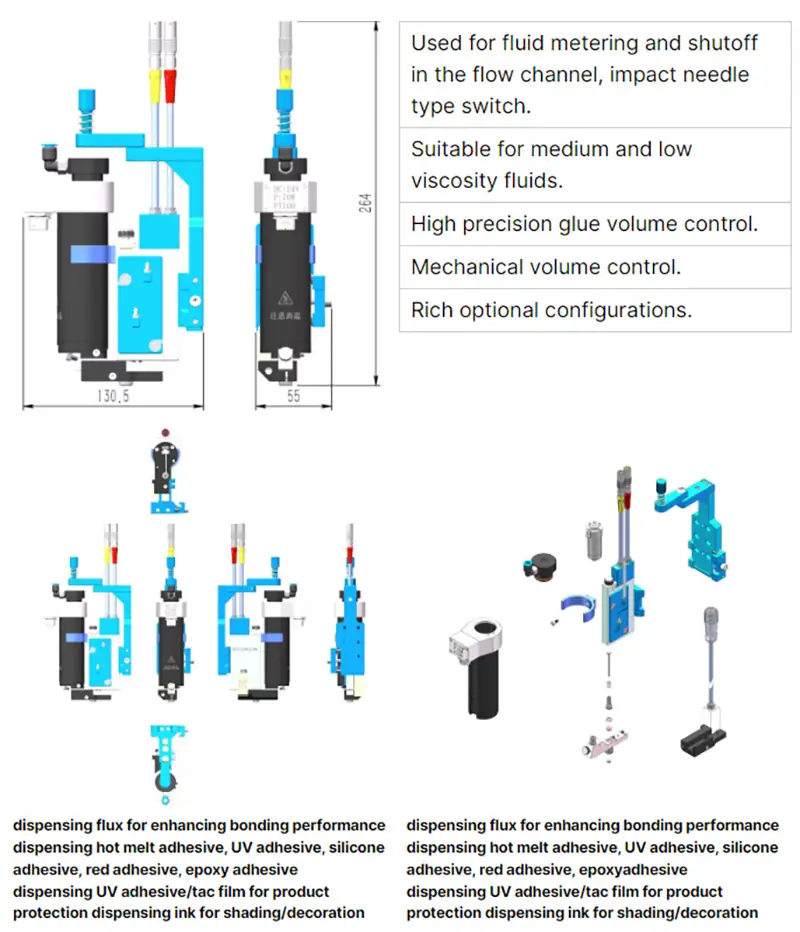

Second Piezoelectric Electric Injection Glue Dispensing Valve

The F-P series piezoelectric injection valve is a single-component volumetric metering valve. Its application scenarios are almost the same as those of pneumatic injection valves, but it uses piezoelectric drive. Compared with pneumatic injection valves, it has a higher dispensing rate and higher glue consistency, and can achieve a smaller amount of glue dispensing! It is widely used in a variety of high-precision dispensing occasions!

● Non-contact dispensing mode

● Fast upper end correction method, eliminating the traditional method of debugging the nozzle

● The highest dispensing frequency is greater than 800Hz

● Achieve micro-control of 200 microns/dot

● High precision glue control accuracy ±1%

● Stable dispensing repeatability

● Standard equipped with adjustable temperature control structure

● Can carry out 232 communication and implement software to modify controller parameters

When voltage acts on piezoelectric ceramics, the piezoelectric ceramics will produce mechanical deformation according to the magnitude of the voltage and the frequency, and cooperate with the spring-driven striker to hit the fluid on the nozzle,thereby ejecting the fluid.

Key attributes

Other attributes

| Place of Origin | Guangdong, China |

| Condition | New |

| Weight (kG) | 5 |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Core Components | valve |

| Warranty | 1 Year |

| Applicable Industries | Manufacturing Plant, glue application industrial, Waterproof, encapsulating, gasket, Power adapter,Toys and gift, PCBA bonding, LCD screen |

| Showroom Location | Viet Nam, Thailand, Malaysia |

| Brand Name | Second |

| Product name | Pneumatic injection glue dispensing valve |

| Driving mode | Electric |

| Flow channel material | stainless steel |

| Strike material | tungsten steel |

| Applicable glue viscosity | 0-100000cps |

| Seal material | PEEK/PTFE/PE |

| Maximum operating frequency | 800HZ |

Specification

| Item | Parameters | ||

| Model: | F-P101 | F-P102 | F-P103 |

| Size | 220*55*105mm | 220*55*105mm | 220*55*135mm |

| Weight | 540g | 600g | 850g |

| Driving mode | electric | electric | electric |

| Flow channel materia | stainless steel | stainless steel | stainless steel |

| Nozzle/strike material | tungsten steel/ceramic |

tungsten steel/ceramic | tungsten steel/ceramic |

| Applicable glue viscosity | 0-100000cps | 0-100000cps | 0-100000cps |

| Sealmaterial | PEEK/PTFE/PE/FKM | PEEK/PTFE/PE/FKM | PEEK/PTFE/PE/FKMM |

| Maximum operating frequency |

800HZ | 800HZ | 800HZ |

| Minimum single point diameter |

0.2mm | 0.2mm | 0.2mm |

| Minimum scribing size | 0.25mm | 0.25mm | 0.25mm |

| Seal life | 1 week | 1 week | week |

| Nozzle/striker life | 3 months | 3 months | 3 months |

| Minimum glue volume | 2nl/point | 2nl/point | 2nl/point |

| Line width accuracy | ±3% | ±3% | ±3% |

| Nozzle heating temperature | / | 20~180-C | 20~180℃ |

| Cylinder heating temperature |

/ | / | 20~200℃ |

Circuit board chip protection, LCM, headset, VCM, FPC protection, mobile phone, fingerprint module and other dispensing applications.

Manufacturing Plant, glue application industrial, Waterproof, encapsulating, gasket, Power adapter, Toys and gift, PCBA bonding, LCD screen

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-1200x208-1.webp)

Our two-component In-line automated vacuum potting system machine is often used in the LED driver, power supply dispensing, with this encapsulated process, the product is heat dissipation, moisture-proof, waterproof, and flame retardant.

EMI and FIP dispensing techniques are widely use in the telecommunication and transportation industries. With the rapid development of communications, electric vehicles, and personal wireless electronic gadgets, these products are often required to connect and interact between each others. However, the signals sometimes interfere with the others, so need to be filtered or shielded. To improve and control the electromagnetic signals, engineers can redesign the entire product, or it can apply EMI shielding materials to filter or shield. Shielding is relatively economical and easy to achieve, it is done basically by adding shielding gasket. Our dispensing machine can directly produce different sizes of triangular shapes or D-shape filtering gaskets, these gaskets can appear in different shapes and is directly applying to the products. The dispensing machine equips with special adhesive material dispensing valve to apply directly, and without post-processing. The machine is intelligent, precise, but user-friendly, without complicated installation, or setup. In addition to the above functions, this type of dispenser equipment can also dispense FIP adhesive glue, and thermal interface material. The equipment is not only precise, but also multi-purpose, which is convenient for various type of storage battery, and electronic product applications.

Dispensing equipment are important for various EMS (electronic manufacturing service) productions. Electronic product processing service industry is indispensable to modern life, because many products are now equips with electronic and become more intelligent. These products are becoming more and more complex, precise and tiny in size. And for consumer product, their production volume also in large production and fast turnover. Therefore, it is necessary to use automated equipment, or even fully automated production lines to produce to meet apply the materials. With the automatic dispensing robots, it is possible to catch up with the capacity and demands. And more importantly, to improve economic efficiency to maximize economic of scale, and so to reduce unit prices to enhance competition. Very often in this type of production, the uses of dispensing machines or equipment is inseparable. In this production process, the glue dispenser is usually used to assist in the functions of fixing, connecting, protecting, dissipating heat and so on between parts and components. Our glue dispensers can directly add the relevant materials to the specified positions accurately and quickly as required.

Two-component materials’ encapsulating and casting production are important to enhance electronic products. No matter if your product is for business selling, or for household consuming, nowadays everyone has higher quality requirements and expectations. Furthermore, the protection of the product is not only to optimize the function of the product, but also to prolong the service life of the product, thereby reducing production waste. In electronic products the parts and components are generally composed of different metals and sensitive chemical combined materials. The more precise the product, the more high-tech the product it is, with this, it requires higher protection, so that it can be optimized according to the requirements. In doing so, it can state of long-term operation without being affected by the surrounding environmental conditions. Our two-component potting machines are specially designed for this production, as well as our vacuum encapsulating and casting potting machines. These machines can accurately degas the two-component adhesive materials base on the ratio, meter, mix, and homogenously and continually to the products. These materials cannot be applying manually, they need to use machines, which can be supplied in large quantities, continuously, accurately, and for long time of works. With the materials provided by such equipment, the product will have better protection, heat dissipation, waterproof, moisture-proof, encryption (to protect the circuitry design, and components used).

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

CE, UL, ISO 9001, and RoHS compliance for global markets.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

SEC-100TD standard included as below 6 parts.

(please check and see if the below parts are fully received when machine is arrived)

● Main unit

● Syringe adaptor

● Syringe holder

● Ø6 Pneumatics tube

● Power cord

● Foot switch

Second Plastic Base Precision Needle

Bent needles are precision bent for specialprocesses and workpiece dispensing, specialsteel tube bending process ensures that thereis no additional increase in fluid passageresistance at the bend, customized bends of 30,45, 60 and 90° are available.

Applicable Industries:

Manufacturing Plant, glue application industrial, Waterproof, encapsulating, gasket, Power

adapter,

Toys and gift, PCBA bonding, LcD screen

Close the glue in advance:

Value range: 0~99mm Recommended value:1~20mm

Open glue in advance:

Value range: 0~99mm Recommended value: based on the actual dispensing

Suitable for 2600 ml silicone sleeve packaging. Easy to operate and maintain. Can communicate with automatic machine . Stable glue output. The glue output accuracy can reach up to ± 3%

Screw pump stator material: FKM corrosion resistant fluororubber

Screw pump rotor material: 304 stainless steel plating

Screw pump connecting rod material: 304 stainless steel (with spiral blade)

Applied range:

Delivery of medium and high viscosity fluids such as silicone, epoxy resin, grease, thermal conductive gel,thermal conductive silicone, and thermal paste